H2CAST Etzel: Large-volume hydrogen storage within reach - article of STORAG ETZEL

"Make energy transition work": The first cavern is to be converted for hydrogen storage by the end of the year.

"Make energy transition work": The first cavern is to be converted for hydrogen storage by the end of the year.

STORAG ETZEL GmbH is the largest independent provider of cavern storage facilities in Germany, contributing to energy security and gas grid stability in Germany and Northwest Europe.

At the Etzel site in East Frisia, the mining company has been building, operating and leasing underground storage capacities for natural gas and crude oil since 1971.

Currently, around 3.9 billion cubic metres of gas are stored in 51 caverns, and a further 24 caverns can store over 10 million cubic metres of crude oil. Another 24 caverns have already been approved. As part of the H2CAST research project funded by the state of Lower Saxony and the federal government, STORAG ETZEL wants to create the conditions to make the cavern facility future and "H2-ready".

The Etzel salt dome, at a depth of over 1,000 m, offers geologically excellent conditions for storing large quantities of hydrogen with high injection and withdrawal rates.

In particular, the Etzel grid hub with its pipeline connections to the European natural gas and future hydrogen transport network and to the deep-water port of Wilhelmshaven, as well as its proximity to the offshore landfalls of renewable energy, offer a wide range of possibilities for the development of an H2 economy in northwest Germany.

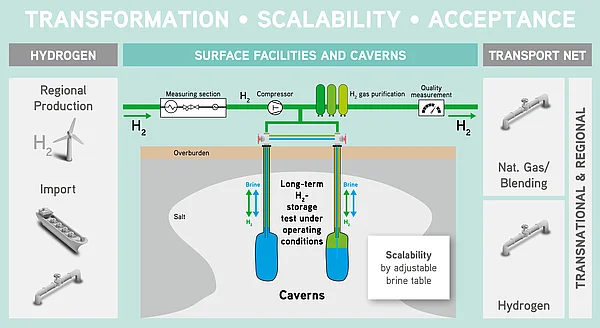

"Make energy transition work": The operator STORAG ETZEL has already successfully converted oil caverns for natural gas storage in its operating history. The H2CAST Etzel research project will now investigate the conversion of underground storage facilities from gas/oil to hydrogen by 2026. H2CAST stands for H2 CAvern Storage Transition, i.e. the rededication of the existing caverns and facilities in Etzel for the future necessary storage of hydrogen as a building block of the future energy system.

The first cavern is to be converted for hydrogen storage by the end of the year. To this end, STORAG ETZEL and its project partners have already carried out extensive material investigations and leak tests with nitrogen and hydrogen on a cavern. The tests have been very successful so far, the gas tightness for hydrogen has been proven as well as the suitability of the existing piping including connections.

After the conversion, operational storage operation is to be tested from next year.

Since the necessary infrastructure for this is not yet available, the cavern operator will use another cavern for the approximately two-year test phase, which will serve as a "hydrogen producer" and "consumer". In other words, the hydrogen is to be shuttled between the two caverns via the local aboveground test facility (gas processing, measurements, compression) without the need for a pipeline connection.

In addition to operation and gas processing, the focus is also on maintenance and servicing of the storage facility under hydrogen conditions. H2CAST thus also serves as a test opportunity for the conversion and development of services for underground storage. Further information on the hydrogen pilot project and the project partners can be found here at www.h2cast.com.