Wellhead technology for hydrogen caverns

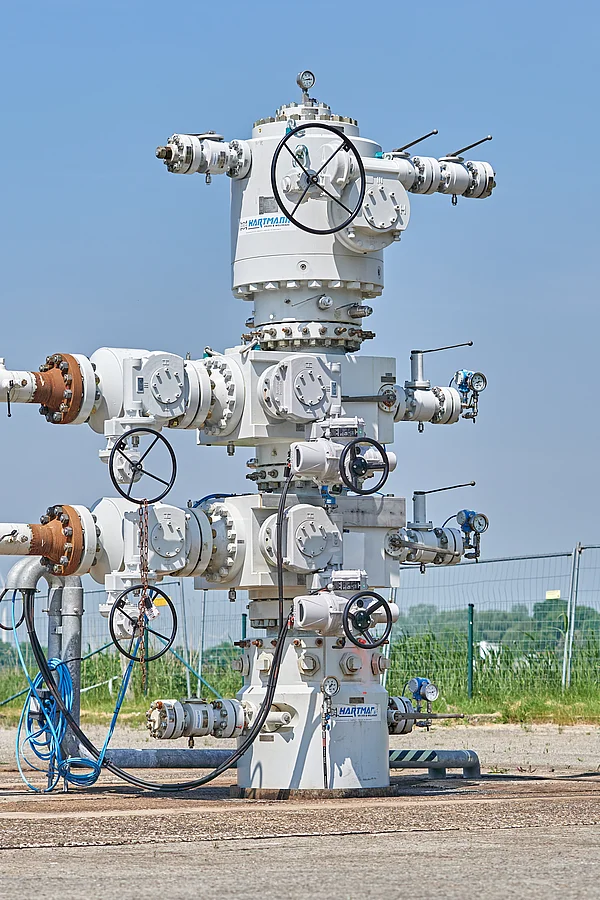

With the start of the North German pilot project "H2Cast Etzel", an optimal design of the hydrogen-compatible wellheads will be developed with the project partner Hartmann Valves.

EEK 2022, Hartmann H2Cast Etzel Wellheads

Authors: Norman Holenstein, Sales & Project Manager, Hartmann Valves GmbH

With the start of the North German pilot project "H2Cast Etzel", an optimal design of the hydrogen-compatible wellheads will be developed with the project partner Hartmann Valves. The focus is on design adaptations regarding maximum operational safety with the demanding medium of hydrogen. In addition, the question is how existing wellheads in the gas caverns could also be converted for hydrogen operation in the future. That means up to which point the wellhead design is transferable and at which points a modification of the wellhead is necessary.

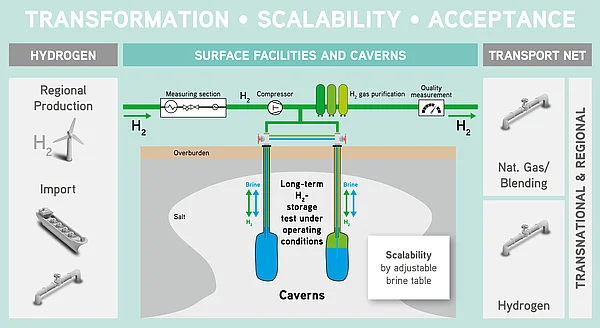

H2CAST Etzel – underground storage of hydrogen

In the hydrogen research and development pilot project, the feasibility of large-volume underground storage of hydrogen will be demonstrated and tested in operational storage operation. H2CAST stands for H2CAvern Storage Transition, which means the conversion of existing caverns and facilities in Etzel for the storage of hydrogen as a building block for a future energy system. The underground storage of hydrogen in caverns is an environmentally friendly solution for storing large amounts of energy in the future to balance generation and demand. Underground cavern storage in salt is ideal for the large-volume storage envisaged. Accordingly, the suitability of the salt caverns at the Etzel site for hydrogen storage is also being demonstrated as part of the project. With currently 75 oil and gas caverns, Etzel is one of the largest cavern fields in Europe. The H2CAST Etzel project includes two caverns with a compressor station and gas drying plant. This offers the great advantage that storage operations including injection and withdrawal between the caverns can be simulated. This allows testing under real conditions, such as temperature fluctuations, or even different pressure situations.

Possible design features

In the first phase of the pilot project "H2Cast Etzel", one of the tasks is to work out the optimal design of the hydrogen-capable wellheads. On the one hand, this concerns the choice of materials and, on the other hand, further seals and measuring points are added to the wellhead and tightness measurements are carried out. Hartmann wellheads are equipped by default with pure metallic sealing ball valves to API 6A which in the standard form have a double seal against the bore pressure.

Furthermore, double sealings at the flange connections as well as additional metallic sealings can be integrated at the wellhead. In order to reduce flange connections also a solid block design is possible, which integrates several components in one block.

Depending on the outcome of the design and the testing of all components in phase 2 of the project, existing wellheads of the gas caverns could also be converted to hydrogen suitable wellheads or, conversely, the new hydrogen wellheads could be converted to gas operation with appropriate adjustments.

Integrated ball valves for maximum safety

The core element for operational safety of wellheads are the shut-off valves. Due to their durability and low maintenance, the use of ball valves has become more and more established in the oil and gas industry as well as in deep geothermal energy. Compared to gate valves, integrated API 6A ball valves at the wellhead offer a higher degree of safety, as they are less likely to blocking, are subject to less wear and do not need to be filled with grease, which could contaminate downstream equipment parts. Hartmann ball valves also have a purely metallic seal between the ball and seat ring and are gas-tight even at pressures of up to 690 bar. The hydrogen ball valves used in the petrochemical industry guarantee gas-tightness even at extremely high temperature ranges. For example, Hartmann has supplied DN 200 PN 420 valves that are switched at 184 bar at 380°C, as well as DN 600 PN 420 ball valves that close reliably at 191 bar and at 426°C. Even with high cycle frequencies, up to 200,000 cycles per year, the ball valves offer reliable and low-maintenance shut-off. Additional safety is provided by the Double Isolation and Bleed (DIB) option or the Twin Ball Valve (TBV) design – double ball valve with up to four barriers in one valve. Testing in the pipeline can be facilitated with the appropriate valve selection by means of the double block and bleed (DBB) function.

Standardised Hydrogen Tests

In addition to hydrogen-capable wellheads and valves, the H2CAST Etzel project also includes accompanying material suitability and leak testing by Hartmann Valves. The right selection of materials as well as standardised pressure tests are essential for the safe use of hydrogen as a medium. For all metallic components in direct contact with hydrogen Hartmann offers standardised material suitability tests. Within the test scope the metallic material selection is evaluated regarding its resistance against hydrogen embrittlement to make sure that it is fit for hydrogen service. Being a small molecule, hydrogen can migrate through sealing elements. A comprehensive pressure test provides assurance that the threshold values are adhered to and fugitive emissions are minimised.

Hydrogen tests also played a decisive role in the first hydrogen storage project 2021, which was supported by Hartmann, in order to decide on the use of existing equipment. Thus, the existing wellhead equipment was first comprehensively tested by Hartmann's material suitability test to avoid material fatigue and hydrogen embrittlement. In addition to the existing hydrogen-suitable parts, Hartmann designed and manufactured new wellhead components, including metal-seated API 6A ball valves. As part of the final Factory Acceptance Test (FAT), a successful hydrogen test for tightness was carried out at Hartmann's site. Hartmann also offers testing of other suppliers' equipment for hydrogen compatibility.