- Further milestone for the conversion of existing caverns for the use of hydrogen in Etzel is being implemented as planned

- STORAG ETZEL: "Want to show that the existing facilities in the Etzel cavern field are suitable for hydrogen storage".

- Injection of 80 tons of hydrogen to begin in summer 2024

Further milestone for hydrogen pilot project H2CAST Etzel to be implemented on schedule

Following the successful completion of the first hydrogen (H2) leakage test for condition assessment in spring this year, work on retrofitting the two H2CAST Etzel caverns for hydrogen storage began last week after intensive planning was completed. In one cavern, a gas storage completion and a brine shuttle string will be installed in the access borehole. In addition, a new cavern head suitable for hydrogen will be constructed.

The "workover operations" by means of a winch are expected to be completed by the end of the year under the supervision of experts from various disciplines and intensive measurements on the wells - in compliance with all required safety standards.

The completion work was approved in advance by the supervisory authority, the State Office for Mining, Energy and Geology (LBEG). This means that another milestone of the hydrogen pilot project H2CAST Etzel is being implemented according to plan.

About H2CAST Etzel

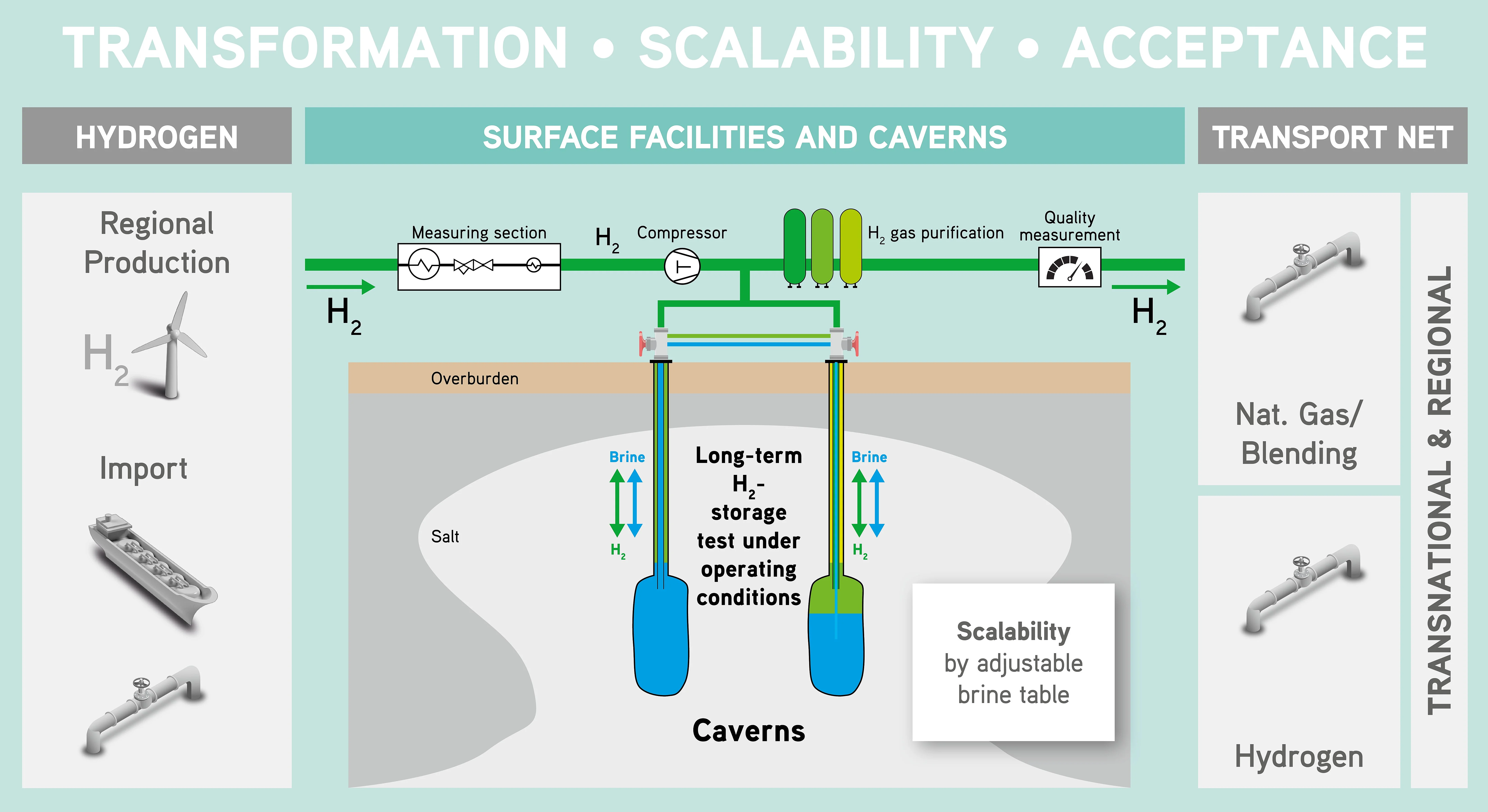

The H2CAST Etzel project aims to demonstrate the feasibility of large-scale underground storage of hydrogen and to prove the suitability of the salt caverns in Etzel for hydrogen storage. The operational use of the hydrogen storage will be tested and will serve to establish a hydrogen industry in Germany and Europe. H2CAST stands for "H2 CAvern Storage Transition", i.e. the rededication of the existing large-volume caverns and technical facilities in Etzel for the future storage of hydrogen as a building block of a renewable and thus ecologically sustainable energy system.

The project is funded by the state of Lower Saxony and the Federal Ministry of Economics and Climate Protection (BMWK).

Proven and safe technology from natural gas storage is used

The components are largely based on suitable technology that is already available on the market and has proven itself in the storage of natural gas over decades. The individual elements will be tested here in real operation with hydrogen; they were previously tested in the laboratory by specialists for their H2 compatibility under artificial hydrogen charging.

Goals of the subsequent H2 demonstration operation

Within the framework of the H2CAST demonstration operation, the long-term suitability under real operating conditions is to be proven. "In particular, we want to show that the existing facilities in the Etzel cavern field are suitable for hydrogen storage without the need to develop new components. This makes enormous economic sense, without any restrictions on plant safety, when the market is ramped up throughout Germany," says Carsten Reekers, head of the H2CAST joint project.

Praise for the project partners

STORAG ETZEL would like to express its gratitude to the partner companies and institutions of H2CAST, who have successfully achieved the project goals in teamwork with diligence and commitment.

Further schedule of the work

Following the completions, further tests will be carried out to check the tightness of the drilling equipment and the salt rock. If the tests are successful, the caverns will be pressurised with 80 tonnes of hydrogen up to the highest permissible pressure. An above-ground test facility will enable gas storage operation with the steps of compression, gas drying and purification, pressure control, volume and quality measurement.

Project results to be published

The Etzel site is to be "H2-ready" by 2026. The research results and technical standards of the showcase project H2CAST Etzel, which is funded by the state of Lower Saxony and the federal government, will subsequently be made available to other hydrogen cavern sites in the region, thus serving as a "blueprint" for the conversion of caverns for future hydrogen storage in Germany.